Discover how DCM’s Preventative Maintenance Service goes beyond routine checkups. Backed by expert technicians and OEM parts, our comprehensive program helps you avoid downtime, extend machine life, and keep your grinder performing at its best—year after year. Click here to request preventative maintenance.

Comprehensive Grinder Care—From Experts Who Know Your Machine:

DCM’s Preventative Maintenance Service Program is more than a checklist—it’s a comprehensive, customizable care plan that ensures your grinder stays in peak condition.

What’s Included:

Our maintenance protocol covers every critical system on your DCM grinder:

- Machine level

- Gib pins retorqued

- Table oil drained and replaced

- Inspection of oiler system and lines

- Review of limit switches and interlocks functionality

- Replacement of rotary union, mist collection filters, PLC battery, and door window

- Replacement of electrical box filters

- Verification of table flatness

- Spindle motor to table dialed in

- Grind table surface

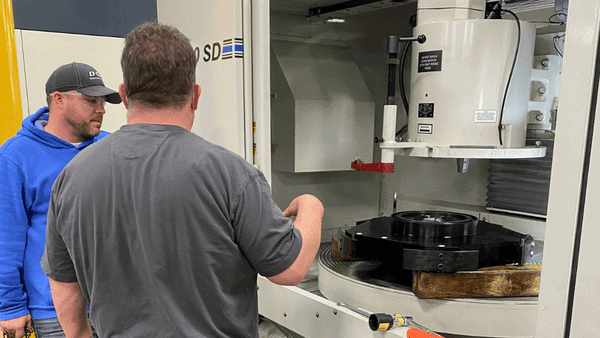

Genuine Parts and Proven Expertise:

Only OEM parts are used, installed by factory-trained technicians who understand the unique demands of your DCM grinder.

Flexible and Proactive:

Whether you need service once or twice a year, DCM offers flexible scheduling and additional services to match your operational requirements.

Genuine Parts and Proven Expertise:

Only OEM parts are used, installed by factory-trained technicians who understand the unique demands of your DCM grinder.

Ready to get started? Contact us today to schedule your DCM Preventative Maintenance Service.

Frequently Asked Questions (FAQs):

- How often should I schedule preventative maintenance for my DCM rotary grinder?

The ideal maintenance schedule depends on your usage level and operating environment. However, a general guideline is to perform routine checks monthly and schedule professional service twice per year. - What does a typical preventative maintenance visit include?

A standard visit includes inspection of critical components (such as the spindle, rotary table, and lubrication systems), cleaning, and replacement of worn parts. You will also receive a service report outlining current machine condition and recommendations. - Can I perform some maintenance tasks myself?

Yes, daily and weekly maintenance—like cleaning surfaces, checking fluid levels, and inspecting visible wear—can often be handled in-house. More complex tasks may also be handled by your maintenance team. There are ‘how to’ videos loaded onto every machine of the preventative maintenance that our OEM-trained technicians perform during preventative maintenance visits, should you choose to do it yourself. If your team does not have time for preventative measures and to ensure your machine is functioning at its best, hire DCM to handle it for you! - How do I know if my grinder needs service soon?

Warning signs include inconsistent finishes, leaks, unusual noises, slower processing speeds, or visible wear on components. If you notice any of these, it’s best to schedule a service appointment immediately. - What are the consequences of skipping preventative maintenance?

Neglecting maintenance can lead to increased wear, unexpected breakdowns, compromised part quality, and higher long-term repair costs—not to mention the risk of unsafe working conditions. - Is a preventative maintenance plan available directly from DCM?

Yes, DCM offers customizable maintenance plans tailored to your specific machine and operating needs. These plans are designed to maximize runtime, reduce costs, and keep your grinder in peak condition.