From Floor to Finish: Dave’s Hands-On Leadership in DCM Machine Assembly

If you’ve ever seen a DCM Tech rotary surface grinder go from raw components to a precision-built machine ready for a customer’s floor, chances are Dave Puetz had a hand in it. As Assembly Supervisor, Dave oversees every phase of the build process, from first bolt to final test. With nearly three decades at DCM Tech, his fingerprints are on hundreds of machines, including nearly every IG Series model built in the last 25 years.

“My day starts about half an hour before anyone else gets here,” Dave says. “I walk through the whole shop, machine shop, paint, assembly, and see where we’re at, what needs to be done, and what might need fixing. From there, I’m answering questions, helping train people, and keeping things moving. I put in about 12,000 steps a day just doing that.”

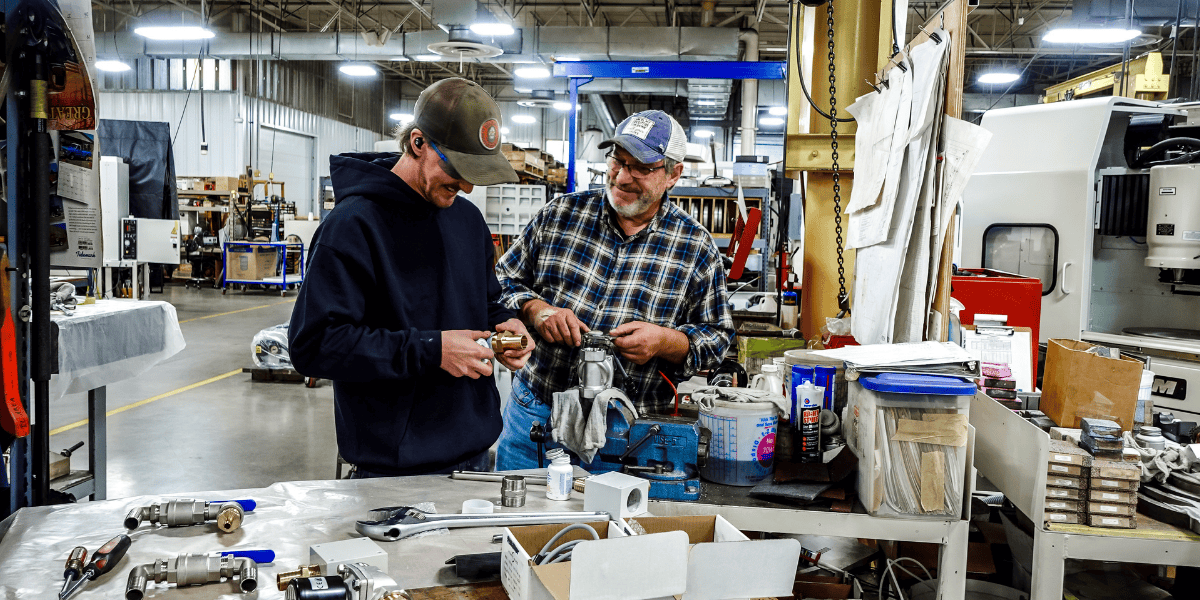

That hands-on presence is what keeps DCM’s builds running smoothly. Whether it’s coaching new assemblers, checking tolerances, or problem-solving in real time, Dave’s focus is always the same: quality over quantity.

Building with Precision and Patience

After 29 years at DCM, Dave knows these machines inside and out. But when asked what skill matters most in his role, he doesn’t hesitate: “Patience,” he says with a laugh. “That, and knowing how the machines are built—how they go together, how the machining process works. Quality is everything in the end.”

His toolbox is full of the fundamentals, calipers, micrometers, wrenches, welders, but his real tools are experience and instinct. “I can usually tell when something’s not quite right just by looking or feeling it,” he explains. “You learn that over time.”

Dave’s work touches nearly every stage of production. “I’m there from the very beginning of the build all the way through shipping,” he says. “I build it down in, grind the table, and make sure everything is proper before it leaves the floor.”

From Farm Equipment to Precision Machinery

Dave didn’t start his career in machine assembly. “I actually started in the shipping department,” he says. “But my main goal was always to get into assembly.”

Before joining DCM, he worked at several implement dealers and went to school for hydrostatic transmissions and engines, skills that translated naturally into DCM’s world of precision machinery. “I used to rebuild tractor engines, transmissions, combines, you name it,” Dave says. “If I could do that, I knew I could do this.”

That background has served him well. “It gave me a foundation in how things work mechanically. It’s all about understanding systems, what goes where, and why.”

A Culture Built on Flexibility and Respect

What sets DCM apart for Dave isn’t just the machines, it’s the workplace culture. “The hours are great, and the building is clean and climate controlled,” he says. “If I need to take care of something for my family, I can. That flexibility means a lot.”

He also appreciates the camaraderie across departments. “We all do different parts of the build, but when it comes down to it, we work together and get the job done,” he says. “Everyone helps everyone. That’s what makes it a good place to work.”

Teaching, Teamwork, and Training the Next Generation

Of all the things he does, what Dave enjoys most is helping others succeed. “I love training people,” he says. “It’s not just about building machines, it’s about helping someone else learn how to do it right.”

DCM supports that growth mindset, offering training and opportunities to move up. “If you’re doing a good job, there’s always a chance to take on more,” Dave explains. “Maybe you start on smaller machines, and once you’ve got that down, you move to bigger builds. There’s always room to grow.”

Pride in Every Build

When asked about projects he’s proud of, Dave smiles. “Up until about six months ago, I had touched every IG 280 we’ve ever built, every single one but two,” he says. “That’s over 200 machines.”

He also recalls a major production milestone: “We had a big order for 37 machines. Everyone had a role, each person was put where they could excel. We worked together, and every machine turned out great. It was a big success for the whole team.”

Life Beyond the Shop

Outside of work, Dave enjoys the simple things. Living in Wabasha, his commute along the river is one of his favorite parts of the day. “It’s a beautiful drive, I get to see the river the whole way,” he says.

When he’s not at DCM, you’ll likely find him restoring old cars, tractors, or tools, or out fly fishing for trout. “Camping and fishing are my go-tos,” he says. “When I’m camping, I’m fishing.”

He’s also spent over 20 years serving his community as a volunteer firefighter, something he looks back on with pride.

And as for retirement dreams? “Waking up, having coffee, taking a walk with my wife, and just saying, ‘I made it,’” he says with a grin.

Why DCM?

For anyone considering joining DCM Tech, Dave offers this advice:

“Be ready to do a lot of different things. It’s not a factory job, you’re not building the same part every day. You’ll learn machining, assembly, problem-solving, everything. It’s hands-on, it’s clean, it’s flexible, and it’s a great place to work.”