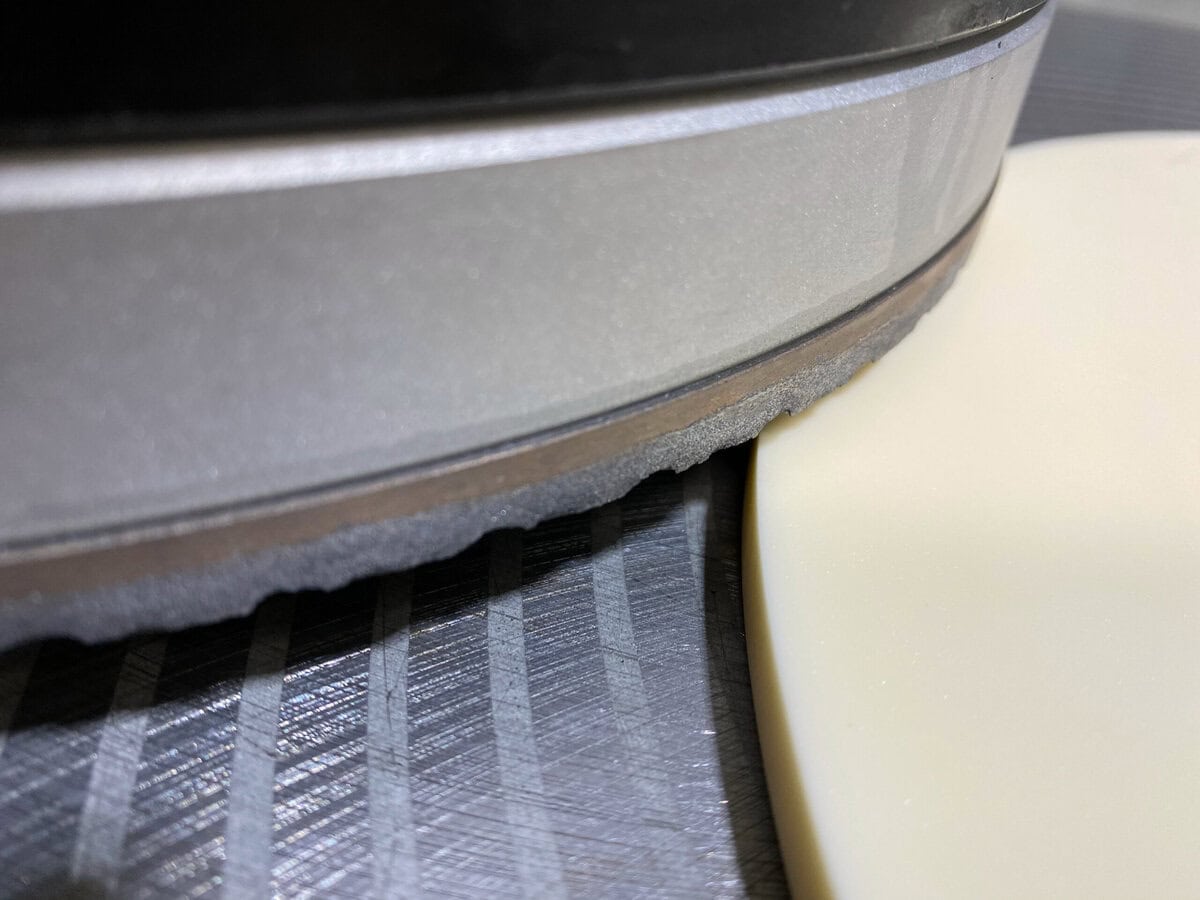

The ceramics industry, particularly in advanced and technical ceramics, requires precision like no other. From aerospace components to semiconductor substrates, ceramic parts demand tight tolerances, flat surfaces, and high mechanical integrity. But machining ceramics is no easy task.

That’s where DCM Tech’s Rotary Surface Grinders come in. Engineered to tackle the most challenging materials, discover how DCM’s grinders offer unparalleled precision, consistency, and durability, making them ideal for ceramic grinding applications.

Challenges in Ceramic Grinding

Ceramics are known for their hardness and brittleness. Unlike metals, they can’t be machined using conventional tools without risking chipping, cracking, or introducing surface stress. Surface finishing is especially critical in:

- Alumina and zirconia components

- Silicon carbide processing

- Ceramic tiles for ballistic and industrial use

- Piezoelectric and ferroelectric devices

- Electronic substrates and insulators

Poor surface finishes can lead to failure in high-stress environments, which is why precision flat grinding is essential.

How DCM Rotary Surface Grinders Elevate Ceramic Manufacturing

1. Cool Grinding for Heat-Sensitive Materials

DCM grinders operate with minimal coolant loss and low heat generation, reducing thermal stress and preventing microfractures common in traditional grinding setups.

2. Automated Precision and Repeatability

DCM grinders offer automated, programmable cycles, and intuitive touchscreen controls, cutting down manual labor and increasing throughput.

3. Superior Surface Quality

Achieve surface finishes as fine as 8 Ra or better, which is essential for medical implants, semiconductor substrates, and ceramic bearings.

Industries Benefiting from Ceramic Grinding with DCM

- Industrial: Machining pump components, valve, and seals

- Defense: Processing armor tiles and ballistic ceramics

- Aerospace: Finishing heat-resistant tiles and insulative ceramics

- Semiconductors: Surface prep of wafers and insulators

- Medical & Dental: Grinding of zirconia crowns and orthopedic implants

Why DCM Grinders Stand Out in Ceramic Applications

✔️ Minimal vibration to protect fragile parts

✔️ Closed-loop control systems for consistent material removal

✔️ Customizable tooling and fixturing for complex shapes

✔️ Long machine life, even under extreme wear conditions

The ceramics industry depends on precision, and DCM Rotary Surface Grinders deliver. DCM grinders help manufacturers meet strict specs with speed, repeatability, and quality, all while reducing operational costs.

Frequently Asked Questions (FAQs):

1. Can DCM rotary grinders handle brittle ceramic materials? Yes. DCM grinders are engineered for delicate materials, using precise controls and low-force fixturing to prevent chipping and cracking.

2. Can I achieve a high-gloss or polished finish on ceramics with DCM grinders? DCM grinders can achieve ., though final polishing may require secondary finishing depending on the material.

3. What’s the average cycle time for grinding a ceramic part? Cycle time depends on part size, material, and depth of cut, but DCM grinders significantly reduce total processing time compared to traditional methods.

4. Can DCM grinders be used in cleanroom environments? Yes, with the right dust collection and coolant containment systems, DCM machines can be installed in controlled environments.

5. Do DCM grinders require specialized tooling for ceramics? While standard tooling can be used, custom fixtures are often recommended to maximize precision and protect delicate parts.

6. How does DCM improve ceramic part flatness? The rotary grinding process naturally promotes uniform material removal, ensuring flat and parallel surfaces critical for assembly and performance.

7. Where can I request a quote or demo for ceramic grinding equipment? Visit www.dcm-tech.com to explore product options, request a quote, or schedule a live or virtual machine demo.