From Concepts to Completion: Erik’s Role in Driving Innovation at DCM Tech

If you ask Erik what a typical day looks like for him at DCM Tech, he’ll tell you the truth: there’s no such thing as a typical day. With responsibilities that stretch across engineering, production, automation, vendor management, and customer collaboration, Erik is one of the key people keeping DCM’s operations moving forward, sometimes all at once.

“I kind of gave up on planning my days,” he says. “In a small company, there’s always a lot going on. My main job is to keep everything moving, getting machines out on time, getting new designs to the floor, answering questions, solving problems, and filling in the blanks wherever we need it.”

It’s a fast-paced role, but one that suits Erik’s energy, curiosity, and leadership style.

Staying Connected and Keeping Communication Flowing

One of Erik’s strengths is staying highly aware of what’s happening across the company. He makes it a point to talk to everyone, from engineering and office staff to machinists and assemblers on the floor.

“I try to talk to everybody at least once a day,” he says. “You get better ideas and better feedback when people feel comfortable talking to you. And problems never get too big when everyone knows they can bring something up right away.”

That openness helps spark new ideas, streamline processes, and strengthen collaboration across teams.

Putting Every Machine Through Its Paces

Although his role spans many areas, Erik stays hands-on, especially when it comes to testing customer machines before they ship.

“I try to run all the IG 180s and bigger machines, especially anything with automation,” he explains. “I run them the way a customer would. A lot of these customers I’ve met or worked with directly, so I know how they use the machine. If there’s something new they need to know about, it’s better we catch it here.”

That customer-minded approach ensures that when a machine arrives on-site, it performs exactly the way the end user expects.

A Second-Generation Story

For Erik, DCM Tech isn’t just where he works, it’s where he grew up.

He’s a second-generation DCM employee. His father has been with the company since 1985, and long before Erik officially joined the team, he spent nights and weekends in the shop working on race car projects and learning the fundamentals of machining and fabrication.

“When I came to work here, I already knew half the people,” he says. “DCM played a big role in my childhood.”

A Role That Spans the Entire Build Process

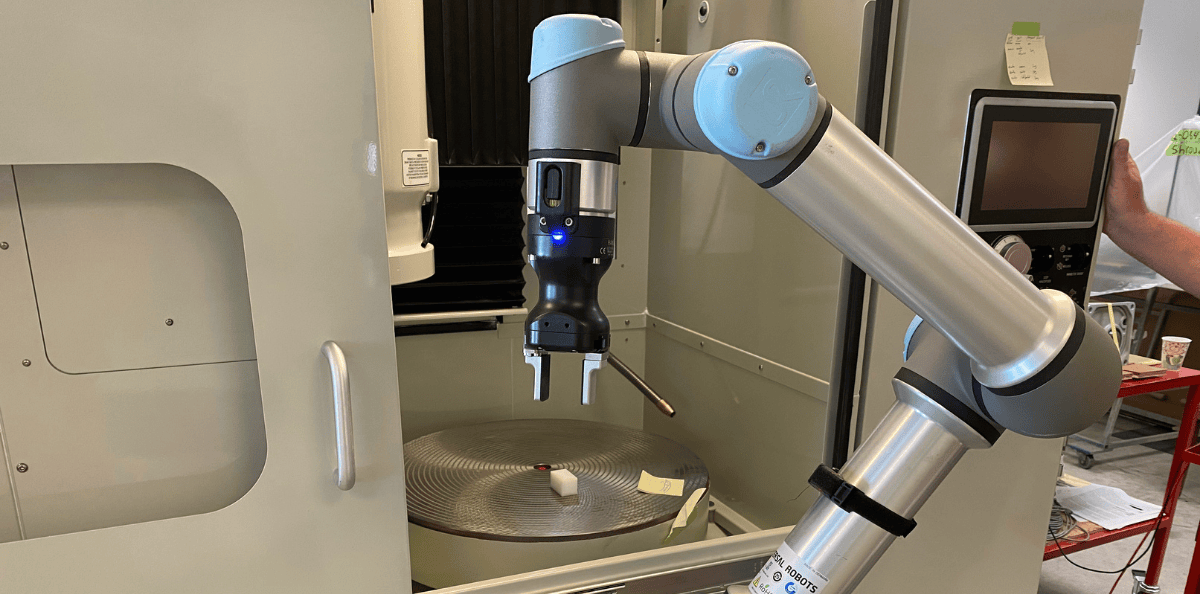

Whether it’s reviewing a customer order before release, coordinating custom fixtures, integrating automation solutions, or collaborating with third-party robotic systems, Erik’s work touches nearly every step of a machine’s journey from concept to completion.

One current project involves pairing a brand-new grinder with an eight-year-old machine, both a robot feeding, handling roughing and finishing operations.

“It’s a heavy automation project,” Erik explains. “Old technology talking to new technology, big parts, lots of them. These customers want everything to work when it arrives, and we’re doing everything we can to make that happen.”

What Makes DCM Different

For Erik, the biggest difference between DCM and other manufacturers is the sheer scope of what happens under one roof.

“People are always surprised by how much we actually build in-house,” he says. “We don’t just assemble, we machine, wire, paint, program, design, and build major components like our own large motors. From raw iron to finished machine, it all happens here.”

It’s not just “Made in the USA.”

It’s “Made within 100 miles of Winona, MN.”

A Culture That’s Evolving

DCM is currently experiencing a generational shift as several long-tenured employees retire. With them goes decades of tribal knowledge, skills not found on any print or CAD model.

“It wasn’t unusual to have people here 30 or 40 years,” Erik says. “Now we’re working hard to document everything and overlap new hires with veterans before they leave. It’s a big change, but a necessary one.”

Despite the transition, he’s optimistic: “We’ve gotten some great new people. We just need one more strong mechanical mind, and we’ll be in great shape.”

Always Something New to Tackle

What Erik enjoys most about his role is the variety.

“I never do the same thing all day,” he says. “I don’t sit still well—I like moving from one task to another, solving different problems. This job fits me perfectly.”

Supporting Growth, Education, and the Next Generation

DCM’s support for training and development is something Erik values deeply. The company maintains strong relationships with Southeast Technical College, Winona State, and St. Mary’s—and offers generous tuition support for employees and their children.

“If you need a class, you take the class,” he says. “We make it work. We flex schedules, reimburse tuition—whatever someone needs to grow.”

Rooted in Winona

Born and raised in Winona, Erik appreciates the strong industrial community and family-friendly environment.

“There’s not much you can’t do within 20 miles of here,” he says. “It’s a great place for kids, great schools, and a lot of industry for a small town.”

He also serves on the Foundation Board for Southeast Technical College and the Mechatronics Advisory Council—helping guide the future workforce.

Family, Racing, and Teaching Teens to Drive

Life outside of DCM is just as fast-paced.

Erik and his children participate in drag racing, with his 13- and 15-year-olds piloting junior cars at speeds up to 75 mph. His family also volunteers at teen driving clinics each spring and fall, teaching emergency maneuvers, skid control, and safe driving habits.

“Helping kids become confident drivers is incredibly rewarding,” he says.