Building More Than Machines: Mike’s Story at DCM Tech

If you’ve seen a DCM machine in action, there’s a good chance Mike Daley has a hand in bringing it to life. With 40 years of experience at DCM Tech, Mike is not only one of the most seasoned members of the team, but also a key part of the machine assembly process, working on multiple builds at once and helping ensure each piece of equipment meets the highest standards before it ever reaches a customer.

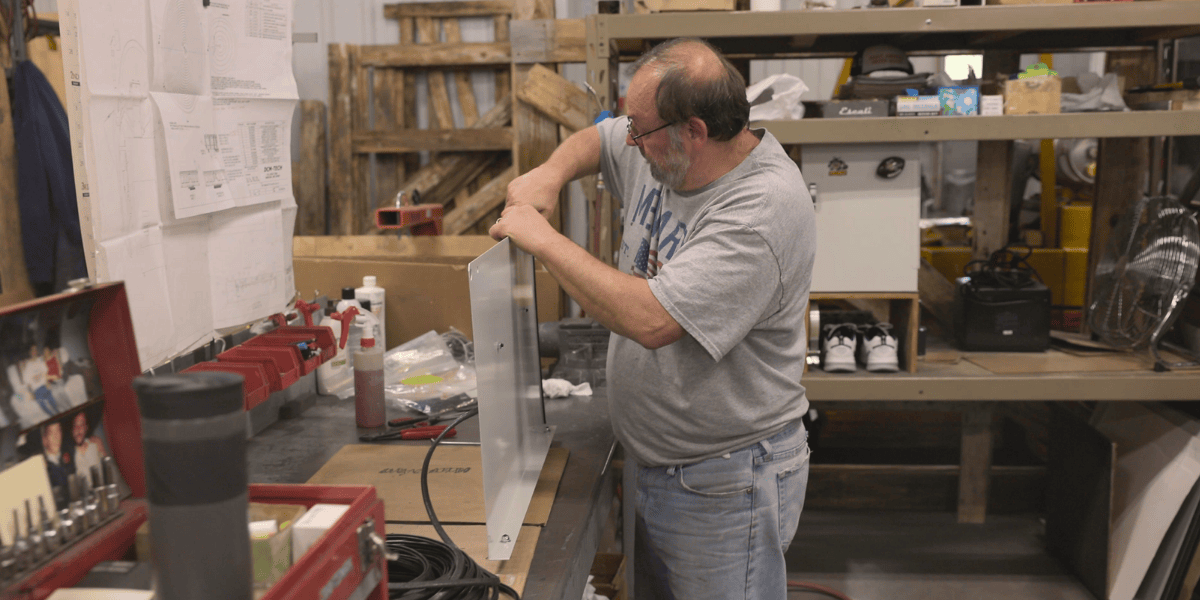

“My day usually starts with checking the priorities for the day,” Mike explains. “Then I jump into whatever needs to get done. Sometimes it’s subassemblies, sometimes it’s full machine assembly. It really depends on the projects we’re working on. I might be building two or three machines at the same time.”

Precision and Problem Solving

In Mike’s role, the smallest detail can make the biggest difference.

“One of the most important things in this job is attention to detail,” he says. “You must know the machine you’re working on that day, read the prints carefully, and sometimes mark them up and bring those changes back to the engineers. That way, the next person who uses that print has a better shot at doing their job right. It’s all about continuous improvement.”

His mechanical mindset started long before his time at DCM.

“I’ve always liked mechanical things,” Mike says. “Taking things apart, putting them back together, fixing them. This job gives me the chance to do all of that while learning something new and challenging myself. And when you finish assembling a machine and know it’s going out there to help someone make other parts, that’s a good feeling.”

A Crucial Step in the Build Process

Mike’s work takes place after a machine is sold, and the build process begins. His position falls just a few steps before final product checkout.

“I’d say I’m probably the third to last person who works on a machine before it gets shipped out,” he says. “I do a kind of review on it, making sure everything is working the way it’s supposed to, before it goes to Gary Puetz. It’s our own kind of quality control before it leaves the shop.”

The DCM Difference

Having spent time in other workplaces over the years, Mike knows what sets DCM apart.

“The biggest difference is the customization,” he says. “DCM builds machines to meet the specific needs of customers. That makes it more interesting and more challenging. You’re not just building the same thing repeatedly.”

But it’s not just the work that makes DCM unique, it’s the culture.

At DCM, experience doesn’t mean your voice gets lost in the shuffle. In fact, it’s just the opposite.

“We’re in a position where we can go to the owners with an idea or an issue and it gets addressed right away,” Mike says. “You don’t get that at a big company. Here, you’re listened to.”

That supportive environment helped Mike face one of the biggest personal challenges in his role.

“I lost some of my hearing back in 2009,” he shares. “But DCM was great about it. People talked louder and adjusted. They made it easy for me to keep doing my job and doing it well.”

Life in the Bluff Country

“It’s beautiful here,” he says. “You don’t always appreciate what you have, but it really is a great place to live. You get to enjoy all four seasons.”

In his free time, Mike enjoys hunting and spending time with his wife.

“We like to take a lot of short trips,” he says. “Sometimes longer ones, too. We’ve been to Mexico quite a few times. We just enjoy spending time together.”

Why DCM?

For Mike, it all comes down to the people, the product, and the pride in the work.

“It’s a good place to work,” he says. “Whether you’re a machinist, in assembly, or in the office. It’s a place where you’re treated well, and you’re part of something that’s being built to last.”

After 40 years on the floor, Mike knows exactly what it takes to build more than just machines—he’s been doing it his whole career.