As the additive manufacturing industry continues to grow and evolve, so too does the need for high-precision post-processing technologies. One of the most critical stages in the 3D metal printing process is surface finishing—where accuracy, repeatability, and surface quality directly impact the functionality and performance of the final part.

DCM Rotary Surface Grinders, provide grinding technology for manufacturers looking to streamline post-processing while achieving unmatched surface precision.

What Are DCM Rotary Surface Grinders?

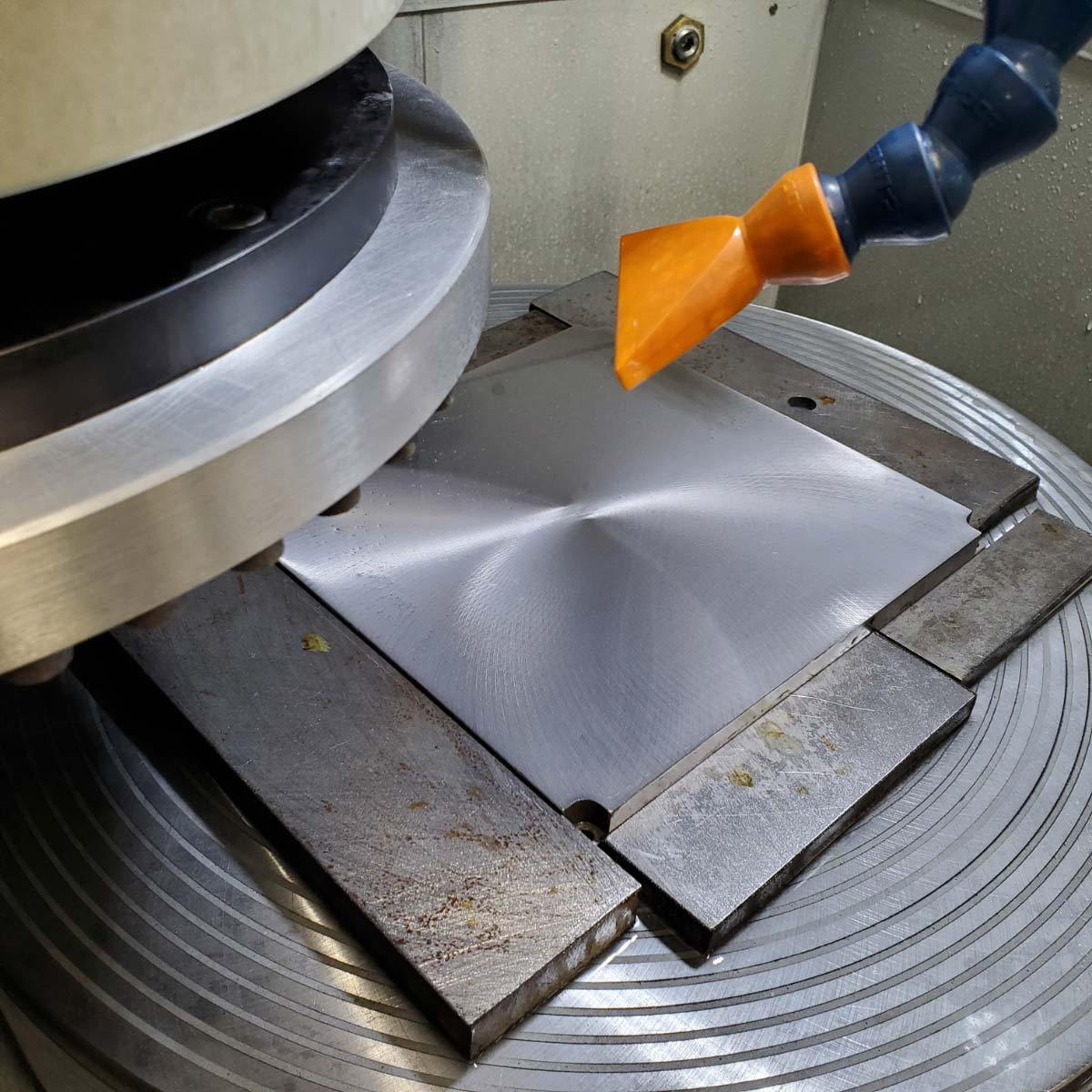

DCM Tech, Inc., a leader in surface grinding innovation, designs and manufactures rotary surface grinders specifically engineered for precision applications. These grinders use a rotary table to hold the workpiece, allowing for uniform material removal across complex geometries with minimal operator intervention.

With intuitive controls, robust design, and advanced automation features, DCM grinders are built to meet the demands of modern manufacturing environments, especially where tight tolerances, flat finishes and a clean work environment are required.

The Intersection of Grinding and Additive Manufacturing

In additive manufacturing (AM), particularly in metal 3D printing, components often require post-processing to meet dimensional and surface specifications. Technologies like Direct Metal Laser Sintering (DMLS), Electron Beam Melting (EBM), and Binder Jetting can leave parts with rough textures or slight warping.

Here’s where DCM rotary surface grinders come in:

1. Superior Surface Finishing

Achieving a consistent, high-quality surface finish is crucial for parts used in aerospace, medical, and automotive industries. DCM grinders offer a precise servo-driven z-axis and automated dressing, ensuring repeatable finishes ideal for tight-tolerance AM components.

2. Precision and Flatness

3D printed metal parts often require flatness corrections. DCM’s rotary technology ensures parallelism and flatness down to 0.0002, which is essential for assemblies and critical mating surfaces.

3. Reduced Post-Processing Time

Compared to manual lapping or belt sanding, DCM surface grinders significantly reduce labor costs and cycle times, allowing for higher throughput in additive manufacturing operations.

Why Choose DCM Grinders for Additive Manufacturing?

✔️ Automation-Ready

DCM machines can be integrated with robotic tenders, vision systems, and IoT monitoring.

✔️ Touchscreen Interface & Programmable Settings

Our intuitive touchscreen interface simplifies programming and reduces operator training time—critical in fast-paced AM workflows.

Applications in Key Industries:

- Aerospace: Surface grinding of turbine blades and structural parts after 3D printing.

- Medical Devices: Finishing orthopedic implants and surgical instruments.

- Automotive: Precision grinding of performance engine components from metal AM processes.

- Tooling: Refurbishing and refining 3D-printed molds and dies.

As additive manufacturing continues to disrupt traditional production methods, so must the tools that support its growth. DCM Rotary Surface Grinders provide the precision, automation, and speed necessary to elevate AM parts to production-ready quality.

Whether you’re a metal AM service provider or an OEM integrating additive technologies, investing in a DCM grinder is a smart move toward efficiency, scalability, and superior product quality.

Frequently Asked Questions (FAQs):

1.What is a rotary surface grinder? A rotary surface grinder uses a rotating worktable and a grinding wheel to precisely remove material and produce a flat surface. DCM rotary grinders are known for their accuracy, repeatability, and minimal setup time.

2. Why is surface grinding important in additive manufacturing? Surface grinding ensures flatness, smoothness, and dimensional accuracy—critical in additive manufacturing where printed parts often have rough surfaces or slight warping.

3. How do DCM rotary grinders compare to traditional grinders? DCM grinders are faster, more automated, and easier to use. Their touchscreen interface and rotary design allow for greater precision and consistency compared to manual or belt grinding systems.

4. Can DCM grinders handle metal 3D printed parts? Yes. DCM rotary surface grinders are ideal for post-processing metal parts produced by DMLS, EBM, Binder Jetting, and other additive manufacturing techniques.

5. What materials can DCM rotary surface grinders process? They can handle a wide range of materials including stainless steel, titanium, Inconel, them versatile for AM and conventional parts.

6. How accurate are DCM surface grinders? DCM grinders deliver accuracy with tight tolerances in flatness and parallelism, making them perfect for aerospace, medical, and automotive applications.

7. Are DCM grinders suitable for high-volume production? Yes. With quick changeovers, automated cycles, and consistent output, DCM rotary grinders are ideal for both prototyping and high-volume post-processing.

8. What size parts can DCM grinders handle? DCM offers models with various table sizes, capable of processing small precision parts to large AM builds, depending on your application needs. Contact a Technical Specialist to learn more.

9. Where can I buy or request a demo of a DCM rotary surface grinder? You can explore product specifications, request a quote, or schedule a live demo.