For manufacturers and inspectors working with critical metal components, quality assurance is non-negotiable. When even the smallest defect can lead to system failure, robust non-destructive testing (NDT) becomes an essential part of the process.

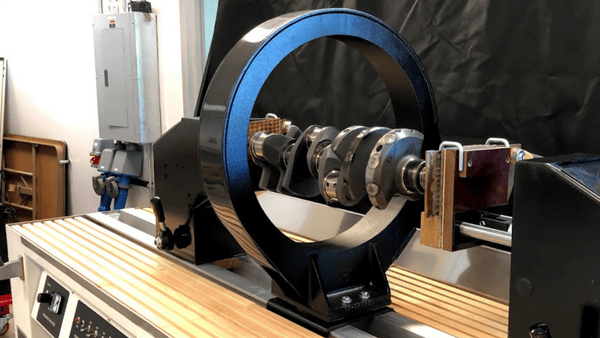

Among the most trusted NDT methods is Magnetic Particle Inspection (MPI), a technique widely adopted across industries to detect surface and near-surface flaws in ferromagnetic materials. DCM Tech, Inc. is known for delivering dependable, high-performance inspection equipment tailored to the demands of industrial-scale operations.

What Is Magnetic Particle Inspection (MPI)?

MPI is a powerful non-destructive method for identifying discontinuities in ferromagnetic metals like steel, iron, and nickel-based alloys. The process works by magnetizing the component and applying magnetic particles to its surface. Any disruptions in the magnetic field—caused by cracks or void-attracting the particles, making flaws visible to the inspector under UV light.

This technique is fast, repeatable, and effective, especially for detecting fine cracks that are difficult to identify using other methods.

Why DCM Tech?

DCM Tech is a U.S.-based manufacturer specializing in rotary surface grinders, and non-destructive testing equipment. Our MPI systems are known for durability, adaptability, and ease of use—trusted by industries where component failure is not an option, including:

- Aerospace

- Automotive

- Military and defense

- Oil and gas

Key Features of DCM Tech’s MPI Machines

DCM Tech offers horizontal and vertical wet bench MPI systems designed for reliability, flexibility, and high-performance operation. Our systems feature:

- AC and AC/DC magnetization options

- Integrated demagnetization

- Heavy-duty, industrial-grade coils

- Manual part handling

These machines can accommodate a wide range of parts, from small engine components to large structural castings, making them highly versatile.

What Sets DCM Tech Apart?

Here’s what makes DCM Tech’s MPI systems standout:

- Consistent defect detection

- Customizable configurations for various applications

- User-friendly controls and ergonomic design

- Environmentally compliant design

- Made and supported in the U.S.

When your inspection requirements go beyond standard configurations, DCM Tech’s in-house engineering team offers custom tailored solutions, from larger coils to advanced fixturing features.

Full Lifecycle Support

DCM Tech doesn’t stop at manufacturing, they offer a full range of service and support to keep your systems running at peak performance:

- On-site and remote training

- Preventive maintenance

- Spare parts availability

- Retrofit and upgrade solutions

- Ongoing technical assistance

Frequently Asked Questions (FAQs):

-

What is Magnetic Particle Inspection (MPI)? MPI is a method to detect surface and subsurface flaws in ferromagnetic materials using magnetic fields and fine particles.

- Who is DCM Tech? DCM Tech is a U.S. manufacturer of machine tools and NDT equipment, offering MPI systems used in aerospace, defense, automotive, and more.

- What types of MPI machines DCM Tech offer? We specialize in horizontal and vertical wet bench systems with features like AC/DC magnetization, integrated demag, and custom fixturing options.

- What are the advantages of DCM Tech MPI systems? Durability, accuracy, U.S.-based support, and customizable configurations.

- Are these machines customizable? Yes. Contact your DCM Technical Specialist for more information.

- What support services do DCM Tech provide? Training, maintenance, technical support, spare parts, and upgrade solutions.

- Which industries use DCM’s MPI machines? Industries like aerospace, automotive, high-performance racing, military, transit, and energy—where reliability is paramount.

- Are the machines environmentally compliant? Yes. They include features like energy-efficient lighting, and use of water-based suspensions in line with EPA/OSHA standards.

- Is MPI the right inspection method for my needs? MPI is ideal for detecting flaws in ferromagnetic parts near the surface. For internal flaws, consider ultrasonic or radiographic testing.

- How can I get a quote or schedule a demo? Click here to request a quote or arrange a product demonstration.

Why Choose DCM Tech?

DCM Tech delivers more than just machines, we deliver confidence. With a commitment to American manufacturing, custom engineering, and client-first service, our MPI systems help ensure that every component you inspect meets the highest standards of quality.