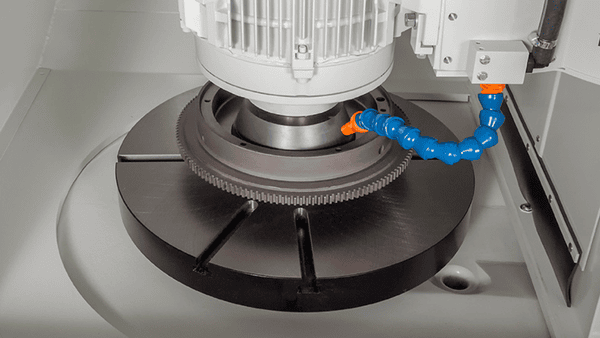

When selecting equipment for resurfacing flywheels, pressure plates, and rotors, the quality and precision of your machinery can greatly influence your shop’s reputation. The DCM Tech SG7000 is a high-performance flywheel grinder trusted in both automotive repair and heavy-duty diesel service applications.

A Tradition of Innovation and Durability

The flywheel grinder is a cornerstone of DCM Tech’s history—it was the first machine developed when the company was established 50 years ago. Since that time, DCM Tech has earned a reputation for manufacturing robust, long-lasting equipment. Today, thousands of DCM flywheel grinders remain in operation across the country, including many units built in the 1970s that continue to deliver dependable performance.

This overview addresses common questions about flywheel grinding machines and highlights the features that make the SG7000 a preferred choice.

Frequently Asked Questions

Q: What is the most suitable flywheel grinder for automotive or diesel applications?

A: The SG7000 is recognized for its versatility and reliability in both automotive and heavy-duty diesel settings. Its precision vertical spindle, rugged construction, and digital controls make it well-suited for high-volume workshops, performance shops, and commercial truck service centers.

Q: Can the grinder surface both flat and stepped flywheels?

A: Yes. The SG7000 accommodates both flat and stepped flywheels through adjustable tooling and precise depth control, ensuring accurate geometry for optimal clutch engagement and reliable operation.

Q: What materials can the SG7000 process (cast iron, steel, aluminum)?

A: The machine is capable of grinding various materials, including:

- Cast iron (commonly used in OEM flywheels)

- Steel (used in performance and heavy-duty applications)

- Aluminum with steel inserts (found in high performance and racing setups)

DCM offers a selection of abrasive options to suit different materials and surface finish requirements, enabling operators to achieve required surface finishes.

Q: How does flywheel grinding compare to turning or machining in terms of accuracy?

A: Flywheel grinding with a vertical-spindle grinder like the SG7000 provides superior flatness and surface finish compared to traditional lathe turning. It ensures:

- Uniform material removal

- High-precision surface finishes (RA as low as 15–20 microinches)

- Consistent results across a variety of shapes and materials

This level of accuracy is crucial for optimal clutch performance and durability.

Q: Can the machine also resurface clutch pressure plates?

A: Yes. The SG7000 can resurface both flywheels and clutch pressure plates, providing a comprehensive grinding solution. Proper resurfacing ensures maximal contact and friction, reducing slippage and uneven wear.

Q: Who manufactures American-made flywheel grinders?

A: DCM Tech Inc., based in Winona, Minnesota, is a leading manufacturer specializing in flywheel and surface grinding machines. Founded in 1975, DCM Tech is committed to producing high-quality, durable equipment and offering comprehensive support. Purchasing a DCM machine supports American manufacturing, with readily available parts and service for both new and legacy models.

Key Benefits of the DCM SG7000

- Precision vertical spindle for accurate grinding

- Digital downfeed and depth control

- Compatibility with flat and stepped flywheels

- Capable of processing cast iron, steel, and aluminum materials

- Multiple abrasive options for tailored finishes

- Compact, user-friendly design

- Made in the USA with dedicated customer support

- Backed by a 50-year legacy and thousands of installations worldwide

For automotive professionals, performance shops, and diesel fleet maintenance providers, the DCM Tech SG7000 offers a reliable investment in quality, efficiency, and customer satisfaction.

To explore how the SG7000 can enhance your resurfacing operations, please contact DCM Tech for a demonstration or quotation.

For further information or to schedule a demo, contact DCM Tech and discover how the SG7000 can optimize your grinding processes.