How is a DCM Grinder different from a Blanchard® by Bourn & Koch?

- Variable Feeds & Speeds: DCM grinders allow you to optimize your grinding process and abrasive wheel performance by having full control over spindle and rotary table speeds.

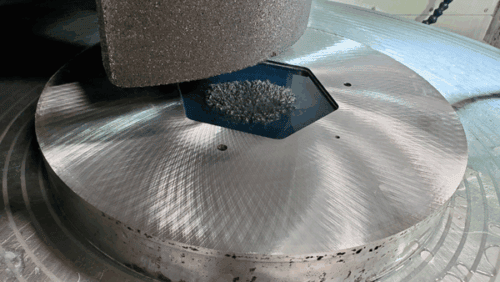

- Rotary Table: DCM’s speed rotary table carries the workpiece under the grinding wheel, creating the characteristic cross-hatch pattern.

- Work–holding: Integrated electromagnetic chucks are standard, with options for vacuum, pneumatic, or hydraulic thru-spindle work–holding, to suit different materials and applications. DCM often co-develops tooling and fixtures to customer’s performance expectations.

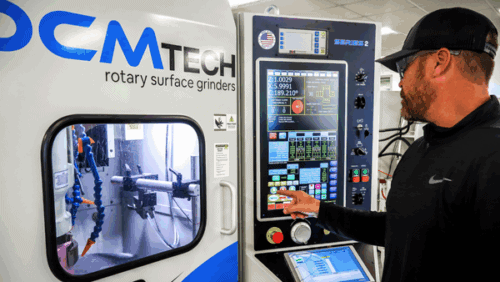

- PLC Controls: PLC Controls on user-friendly HMIs make it easier and simpler for operators to run DCM grinders, enhance overall efficiency, quickly troubleshoot issues, and reduce errors. Once a recipe is defined for a specific part, it can be saved directly on the machine for retrieval whenever it’s needed.

- Customer Service: DCM markets Direct-to-Customer – via our in-house Technical Specialists. These Specialists know the machines inside and out and can assist you with process definition, machine selection, sample grinding, installation, and training/operation. That means your regional Tech Specialist is your dedicated point of contact for service and support, regardless of warranty status—ensuring faster response times and a more personalized experience.

Why should I consider a DCM Grinder?

DCM Tech has 50 years of experience designing and manufacturing rotary surface grinders. Like a machine from Blanchard ® by Bourn & Koch, a DCM grinder offers many benefits:

- Efficiency: Vertical spindle rotary grinding allows for high horsepower input and interrupted grinding, maximizing productivity and higher rates of stock removal.

- Precision: A DCM machine can achieve extremely tight tolerances across the entire work surface and often reduce or eliminate lapping.

- Versatility: Rotary surface grinders are suitable for a wide range of materials, from metals to glass, ceramics and composites.

- Customization: DCM Tech collaborates with customers to develop application-specific control solutions, abrasives, and fixturing.

- In-stock: DCM strives to ship standard base machines from stock in Winona, Minnesota.

While the term "Blanchard grinding" (referring to Blanchard® by Bourn & Koch) is often used generically, DCM Tech has independently developed and refined its own modern solutions—engineered to meet the evolving demands of today's manufacturing environment.

If your grinding involves big parts and deep cuts, you're probably still looking at Blanchard®-style by Bourn & Koch. If it's tight tolerances and high precision in a controlled shop, a new DCM Tech surface grinder might be your pick.

Frequently Asked Questions (FAQs):

-

What is a rotary surface grinder?

A rotary surface grinder is a type of grinding machine that uses a rotating magnetic chuck to hold a workpiece while a grinding wheel moves down vertically to remove material from the surface. This creates an exceptionally flat and smooth finish across the entire face of the part. Unlike traditional surface grinders that use a back-and-forth (reciprocating) motion, a rotary surface grinder spins the part in a circular motion under a stationary or slightly oscillating grinding wheel. This allows for quick, even stock removal and excellent flatness. -

How do I choose the right surface grinder for my application?

Consider factors like material type, part size, required tolerances, production volume, and control features. Modern machines like DCM Tech grinders offer customizable controls, variable speed tables, and advanced workholding for a wide range of applications -

What are the advantages of using a rotary surface grinder?

Rotary surface grinders are known for their speed, precision, and consistent results. They allow for uninterrupted grinding with excellent flatness and finish, making them ideal for production environments. -

How does a modern rotary grinder compare to older models?

Modern rotary grinders feature PLC controls, recipe storage, variable speed settings, and improved safety features. These upgrades improve productivity, reduce setup time, and ensure consistent results compared to legacy equipment. -

Can a rotary surface grinder handle non-metal materials?

Yes. DCM Tech rotary grinders are versatile and can handle materials such as ceramics, glass, and composites, in addition to ferrous and non-ferrous metals. -

Is it better to buy a new surface grinder or refurbish an old one?

While refurbishing an old Blanchard® Grinder by Bourn & Koch can be tempting, a new surface grinder offers better long-term value with modern controls, improved efficiency, warranty support, and reduced downtime.