Achieving high-precision and efficiency results in manufacturing requires a rotary surface grinder with advanced capabilities in tolerance control, automation, and material versatility. From structural rigidity to optimized grinding parameters—that help manufacturers maintain quality, boost efficiency, and meet the demands of critical industries like aerospace and electronics. Enter the DCM rotary surface grinder.

Precision and Tolerance Capabilities:

Look for rotary surface grinders that can achieve extremely tight tolerances, often down to 5 microns or better, to ensure precise flatness, parallelism, and dimensional accuracy of the ceramic components.

This level of precision is crucial for high-performance ceramic applications in industries like aerospace, electronics, and healthcare.

Automated Controls and Sensors:

Advanced rotary surface grinders with sophisticated sensors and automated controls can maintain tight tolerances, detect wheel contact, and automatically adjust parameters like spindle speed and downfeed rate.

This automation helps maintain consistent quality and allows for operation by less experienced personnel. It also lends itself to robotic machine tending.

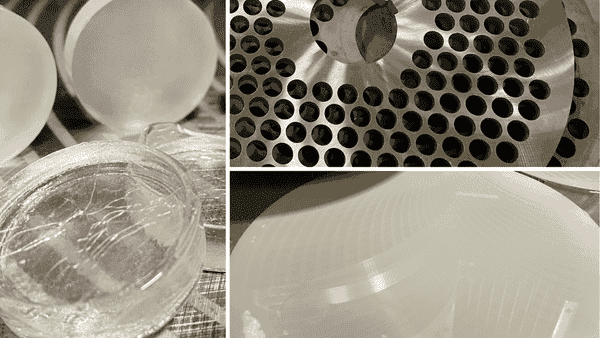

Versatility and Material Compatibility:

Look for grinders that can process a wide range of ceramic materials, including silicon carbide, quartz, and advanced bioceramics, to accommodate your diverse product portfolio.

Ensure the grinder is compatible with the specific ceramic materials you work with, as different abrasives and dressing techniques may be required.

Structural Rigidity and Design:

The structural design of the rotary surface grinder, including the base, spindle, and table, should be highly rigid to maintain precise flatness and parallelism over extended periods of use.

Features like box ways with scraping techniques and hydrostatic bearings can contribute to sustained performance and accuracy.

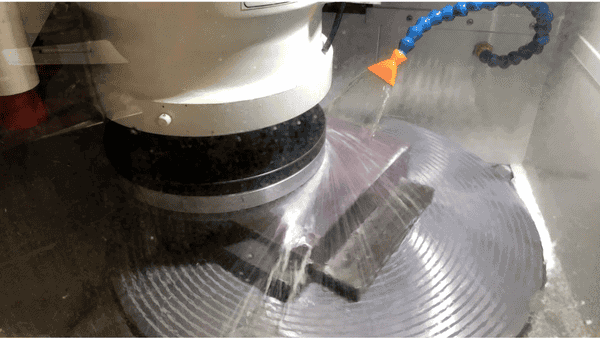

Grinding Wheel and Process Parameters:

Work closely with the grinder manufacturer and abrasive supplier to select the optimal grinding wheel specifications, speeds, feeds, and other process parameters for your ceramic materials and application requirements.

Proper selection and optimization of these parameters can improve efficiency, surface quality, and tool life.

By carefully considering these key factors, ceramic manufacturers can select a rotary surface grinder that will deliver the precision, efficiency, and versatility needed to stay competitive in the industry.